Browse all

- SUBJECT CATEGORIES

- Astronomy and space

- Atomic and molecular

- Biophysics and bioengineering

- Business and innovation

- Condensed matter

- Culture, history and society

- Diversity and inclusion

- Education and outreach

- Environment and energy

- Ethics

- Instrumentation and measurement

- Materials

- Mathematics and computation

- Medical physics

- Optics and photonics

- Particle and nuclear

- Personalities

- Policy and funding

- Projects and facilities

- Publishing

- Quantum

- ARTICLE TYPES

- Collections

- Buyer’s Guide

- Jobs

- EXPLORE PHYSICS WORLD

Refrigerator works by twisting and untwisting fibres

14 Oct 2019

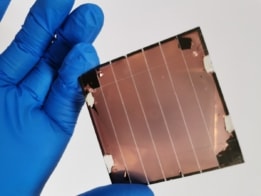

The cooling system relies on the fact that some materials undergo significant changes in entropy when deformed. As far back as 1805 – when the concepts of thermodynamics were first being developed – it was known that ordinary rubber heats up when stretched and cools down when relaxed. In principle, such mechanocaloric materials could be used in place of the gases that change entropy when compressed and expanded in commercial refrigeration systems. Replacing gas-based systems is an important environmental goal because gaseous refrigerants tend to degrade the ozone layer and are powerful greenhouse gases.

In their experiments, Liu and Baughman’s team studied the cooling effects of twist and stretch changes in twisted, coiled and supercoiled fibres of natural rubber, nickel-titanium and polyethylene fishing line. In each material, they observed a surface cooling as high as 16.4 °C, 20.8 °C, and 5.1 °C respectively, which they achieved through techniques including simultaneous releases of twisting and stretching, and unravelling bundles of multiple wires.

Supercoiled fibres

The team also made supercoiled fibres of natural rubber in which the twisting and coiling were done in opposite senses (clockwise and anticlockwise). Much to their surprise, they found that these structures cooled when stretched, rather than heated.The team also looked at microscopic changes in the materials. An X-ray diffraction crystallography study of the polyethylene fishing line revealed changes in molecular structures associated with the transition from low to high entropy phases. The team identified this process as the cause of the effect, which they have dubbed “twistocaloric” cooling.

The team faces many challenges in creating commercially-viable twist fridges, including the need find a material that is not degraded by being repeatedly twisted and untwisted. So far, they have only explored few commercially-available materials, but now plan to expand their research to seek-out materials that have optimized mechanical and twistocaloric properties. If realized on commercial scales, twist fridge technologies could provide climate-friendly solutions to meeting our rapidly expanding demand for cooling.

The research is described in Science.

Sam Jarman is a science writer based in the UK

Related jobs

-

South West England

Research Associate in GaN-on-Diamond Ultra-High Power RF Materials/Devices: University of Bristol

-

Austria

PhD (3 years) and PostDoc (1 year) positions available at Graz University of Technology: Graz University of Technology

-

Sweden

New Director for LINXS: LINXS - Lund Institute of advanced Neutron and X-ray Science

Related products and services

Related events

- Biomaterials | Conference Biopolymer Chemistry and Bionanotechnology – 2019 21—22 October 2019 | Singapore, Singapore

- Thin films and coatings | Workshop VASP Workshop: Electronic Structure Modelling Relevant to Surface and Interface Science 22—23 October 2019 | Chester, UK

- Mathematics and computation | Conference World Congress on Engineering and Computer Science 2019 22—24 October 2019 | San Francisco, US

No comments:

Post a Comment